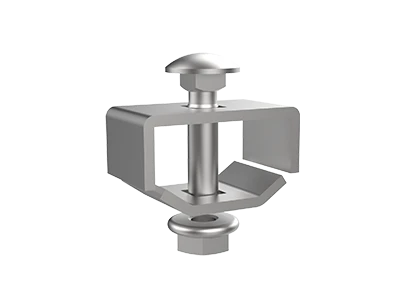

Flag type hanging bracket

Wire mesh cable tray is a highly efficient, flexible, and structurally stable cable management system. It adopts an open metal wire mesh structure to ensure its excellent load-bearing capacity while providing outstanding ventilation performance. In this way, it extends the life of cables, maintains cable performance, and enhance the efficiency of cable management, thereby ensuring the reliability and safety of the cable system.

Its open design greatly facilitates cable layout and subsequent maintenance, making inspection, installation, and replacement of cables quicker and simpler. It is now widely used in various industries and fields including telecommunications rooms, wind power stations, mechanical equipment, and factory cabling.

Features

Specifications

| Height (mm) | Width (mm) | Length (m) | Wire Diameter | Material | Surface Treatment |

|---|---|---|---|---|---|

| 50 | 50, 100, 150, 200, 300, 400, 450, 500, 600 | 3 | 3.5–6 (Common wire diameter is 5 mm) | Carbon steel, aluminum alloy, stainless steel | Powder coated, electrogalvanized, hot-dip galvanized, pre-galvanized |

| 100 | 100, 150, 200, 300, 400, 450, 500, 600 | ||||

| 150 | 150, 200, 300, 400, 450, 500, 600 | ||||

Notes:

|

|||||

Main Parts

Installation & Related Accessories

With the advantage of not occupying floor space, it is suitable for places with high ceilings and is conducive to floor cleaning and maintenance. During installation, it is necessary to ensure that the structure's load-bearing capacity can support the cable tray and its load.

Flag type hanging bracket

T-type hanging bracket

Strut channel bar with KSK

Hold down clip set

It is suitable for shorter cable runs, or where wiring along the wall is needed. Typically uses various types of fasteners and expansion bolts to secure the cable tray, making installation simple and quick.

L-type wall bracket

T-type wall bracket

Cantilever wall bracket

Strut channel wall bracket

It is commonly found in equipment-dense areas or where walls and ceilings cannot be used. By using floor bolts to secure the cable tray, its stability is ensured. Additionally, floor mounting includes two special installation methods: cabinet top installation and underfloor installation.

Applications

Industrial Facilities

Commercial Buildings

Power Systems

Communications Field

Petrochemical